Click image for close-up Click image for close-up

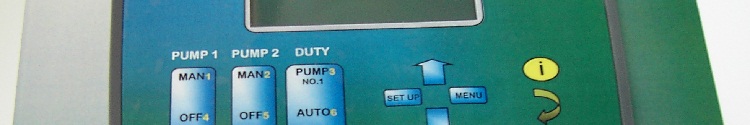

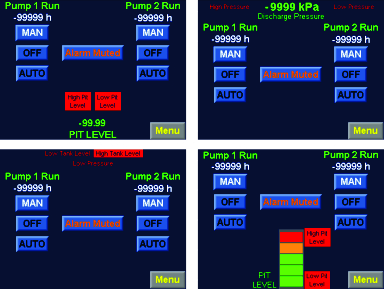

MPS2 (Multi-Purpose Dual Pump Controls)

MPS2 (Multi-Purpose Dual Pump Controls)

IMAGE 21-1:

The Multi-purpose Dual Pump Control Panel has selectable pump operation and can be used for either:

Pressure System using pressure transducer

Pressure System using pressure switches

Sump pump out using level transducer

Sump pump out using level float switches

The INCA MPS2 controller is available in 3 phase up to 11kw 415V and single phase to 1.5kw 240Vac (Larger on request).

The MPS2 controller is designed to accept DIGITAL and ANALOGUE inputs.

This panel is standard with:

Circuit Breakers for each pump and control circuit

Main isolating switch c/w 2nd pole (240V) or 4th pole (415v) for class 1 zone 2 hazardous locations.

Extra low voltage float switch control (1,2,3 or 4 float switch control)

Indication and Control equipment for:

Pump Run, Pump Fail, High Level and Low Pressure and High Pressure

Display of pit level

Manual/Off/Auto

Alarm Mute

Total Hours Run for each Pump

Audible Alarm for each pump fail and high level/ low/high pressure. Alarm silences as per noise regulations.

Voltage Free Contact for each pump run, each pump fail, low level/low pressure & high level

All housed in a wall mounted weatherproof metal enclosure.

Available exras

Ability to add GSM alarm text messaging or

Ability to add Remote Access via Ethernet connection or

Ability to have Remote Acces via NextG Modem

Please note GSM & Remote Access can NOT both be added

|

Click image for close-up Click image for close-up

MPJ2 (Multi-Purpose Dual Pump Controls)

MPJ2 (Multi-Purpose Dual Pump Controls)

IMAGE 2-1:

The Multi-purpose Dual Pump Control Panel has selectable pump operation and can be used for either:

1 float switch timed Standby/High Level Switch Controls

Multi-float switch Stop/Start/Standby/High Level Switch Controls

Timed Alternation/High Level (Automatic Submersible Pumps)

Pressure System Controls

Hot Water Circulating Pump Alternation

The INCA MPJ2 controller is available in 3 phase up to 11kw 415V and single phase to 1.5kw 240Vac (Larger on request).

The MPJ2 controller is designed to accept DIGITAL inputs.

This panel is standard with:

Circuit Breakers for each pump and control circuit

Main isolating switch c/w 2nd pole (240V) or 4th pole (415v) for class 1 zone 2 hazardous locations.

Extra low voltage float switch control (1,2,3 or 4 float switch control)

Indication and Control equipment for:

Pump Run, Pump Fail, High Level and Loss of Prime

Pit level

Manual/Off/Auto

Duty Selection

Alarm Mute

Total Hours Run for each Pump

High Level/ Loss of Prime

Audible Alarm for each pump fail and high level/ loss of prime. Alarm silences as per noise regulations.

Flashing Alarm light on panel roof

All housed in a metal or PVC wall mounted enclosure with inner door.

|

Click image for close-up Click image for close-up

MPJ3 (Multi-Purpose Triplex Pump Controls)

MPJ3 (Multi-Purpose Triplex Pump Controls)

IMAGE 2-2:

The Multi-purpose Triplex Pump Control Panel has selectable pump operation and can be used for either:

1 float switch timed Standby/High Level Switch Controls

Multi-float switch Stop/Start/Standby/High Level Switch Controls

Timed Alternation/High Level (Automatic Submersible Pumps)

Pressure System Controls

Hot Water Circulating Pump Alternation

The INCA MPJ3 controller is available in 3 phase up to 11kw 415V and single phase to 1.5kw 240Vac (Larger on request).

The MPJ3 controller is designed to accept DIGITAL inputs.

This panel is standard with:

Circuit Breakers for each pump and control circuit

Main isolating switch c/w 2nd pole (240V) or 4th pole (415v) for class 1 zone 2 hazardous locations.

Extra low voltage float switch control (1,2,3 or 4 float switch control)

Indication and Control equipment for:

Pump Run, Pump Fail, High Level and Loss of Prime

Pit level

Manual/Off/Auto

Duty Selection

Alarm Mute

Total Hours Run for each Pump

High Level/ Loss of Prime

Audible Alarm for each pump fail and high level/ loss of prime. Alarm silences as per noise regulations.

Flashing Alarm light on panel roof

All housed in a metal or PVC wall mounted enclosure with inner door.

|

Click image for close-up Click image for close-up

MPJA2 (Multi-Purpose Dual Analog Input Pump Controls)

MPJA2 (Multi-Purpose Dual Analog Input Pump Controls)

IMAGE 2-3:

The Multi-purpose Analog Input Dual Pump Control Panel has selectable pump operation and can be used for either:

Sump Pump Control or Pressure System Control with 4-20mA Analog input for Level Or Pressure transducer

The INCA MPJA2 controller is available in 3 phase up to 11kw 415V and single phase to 1.5kw 240Vac (Larger on request).

The MPJA2 controller is designed to accept ANALOG inputs.

This panel is standard with:

Circuit Breakers for each pump and control circuit

Main isolating switch c/w 2nd pole (240V) or 4th pole (415v) for class 1 zone 2 hazardous locations.

Indication and Control equipment for:

Pump Run, Pump Fail, High Level and Loss of Prime

Pit level

Manual/Off/Auto

Duty Selection

Alarm Mute

Total Hours Run for each Pump

High Level/ Loss of Prime

Audible Alarm for each pump fail and high level/ loss of prime. Alarm silences as per noise regulations.

Flashing Alarm light on panel roof

All housed in a metal or PVC wall mounted enclosure with inner door.

|

Click image for close-up Click image for close-up

MPJA3 (Multi-Purpose Triplex Analog Input Pump Controls)

MPJA3 (Multi-Purpose Triplex Analog Input Pump Controls)

IMAGE 2-4:

The Multi-purpose Triplex Analog Pump Control Panel has selectable pump operation and can be used for either:

Sump Pump Control or Pressure System Control with 4-20mA Analog input for Level Or Pressure transducer

The INCA MPJA3 controller is available in 3 phase up to 11kw 415V and single phase to 1.5kw 240Vac (Larger on request).

The MPJA3 controller is designed to accept ANALOG inputs.

This panel is standard with:

Circuit Breakers for each pump and control circuit

Main isolating switch c/w 2nd pole (240V) or 4th pole (415v) for class 1 zone 2 hazardous locations.

Indication and Control equipment for:

Pump Run, Pump Fail, High Level and Loss of Prime

Pit level

Manual/Off/Auto

Duty Selection

Alarm Mute

Total Hours Run for each Pump

High Level/ Loss of Prime

Audible Alarm for each pump fail and high level/ loss of prime. Alarm silences as per noise regulations.

Flashing Alarm light on panel roof

All housed in a metal or PVC wall mounted enclosure with inner door.

|

|